Introduction

(WORK IN PROGRESS)

The heart of an automatic antenna tuner is a good measuring bridge to measure phase and magnitudes of voltages and currents.

U1 provides the Magnitude difference between the Current and Voltage levels.

This means that it will indicate whether Zload > Zo or Zload < Zo.

The Phase output of U1 is not used since it can not distinguisch between capacitive or inductive loads. ( It's phase output voltage will be the same for +45° and -45)

A second AD8302 is used for measuring the Phase difference between the Current and the Voltage signals.

The 90° (or almost 90 )phase shifting is done with R1/C1, this allows us to see if the load is inductive or acting capacitive.

With these two signals a control loop can be arranged to tune the matching circuit.

|

| Fig 1: Simplified working schematic. |

The actual phase shift can be calculated with the formule:

This gives us a phase shift between 89,935° and 88,92° over the range 1.8Mhz...30Mhz.

The phase error is only 1° and can be compensated since we can calculate this using the above formula. Since the AD8302 phase output is 10mV/° .This means we will have to subtract 0.65mV@1.8Mhz to 10.8mV@30Mhz from Vref/2 to get the correct value.

The design uses 2

AD8302 devices to measure phase and magnitude of currents and voltages.

The AD8302 is an excellent choice since it specs range from LF to 2.7 Ghz , and it measures over a 60 db range of input signals.

You can find the datasheet

here.

The first one is used to measure the phase between the voltage and the current to the load.

The second one is used to measure the magnitude between the current and the voltages.

I use two devices because the ad8302 does not see the difference between leading and lagging signals.

By phase shifting one of the inputs -90° , the phase output gets centered around 900mV (Vref/2).

See the graph below:

Note that the 90 degrees will be on the other side if the secondairy of the current transformer is connected in reverse, the same will haven if ANT and TRX are swapped.

Besides these measurements, the bridge also contains a frequency pre-scaler so that a microcontroller can measure the operating frequency so it can drive look-up tables that control motors for tuning a matching circuit.

The (first) prototype:

The bridge is constructed in a 55 * 74 *30 mm tinned RF box.

(some smd parts not yet mounted.)

Detail picture of the current tronsformer wound on a 4C65 ferrite torroid with Litz wire.

(not sure if this is really making a lot of difference compared to a solid wire.)

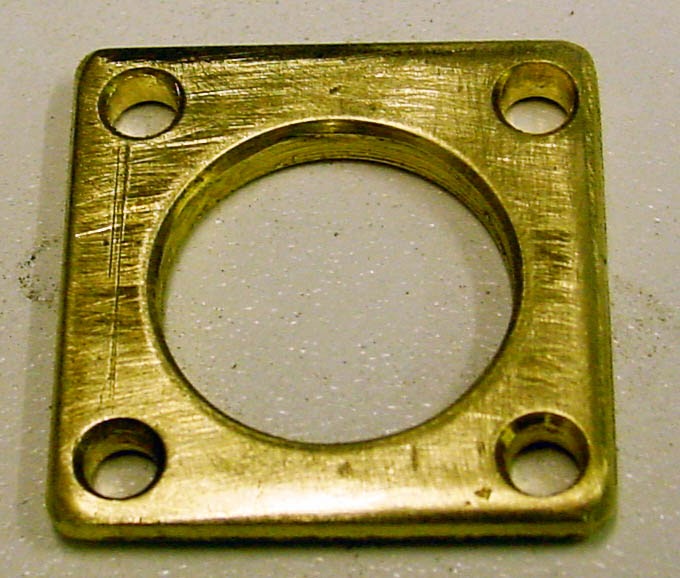

Some of the metal parts are made from brass plate and then silver plated using some (nasty) chemicals (silver cyanide and pottasium cyanide mix).

Before:

After plating :

The inner conductor is made of a piece of thick coax.(aircom plus or similar)

The center conductor is shielded by a piece of copper tube that has been soldered to the plated flanges. This avoids any capacitive coupling between the center conductor and the windings of the current transformer.

Here is an overview of the mechanical assembly.